The coil used for heating the inner surface of a

rocker arm which required hardening the coil comprises two turns positioned so

that they lie adjacent to the surface requiring heating.

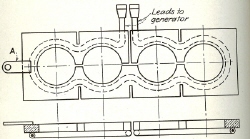

A good many applications of induction heating require the use of coils which

might have two or more windings spaced widely apart to suit surfaces of varying

size. In this case it is important that the paths of the current flow in the

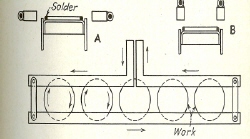

same direction. Assuming that a double-turn coil is desired, like that shown at

A in Fig. 63, the winding arrangement should be such that the current flows in

the same direction, as indicated by the arrows. If a coil were made such as

that as shown at B, with the current flowing in one direction in one coil and

opposite in the other, the magnetic flux of one would have a tendency to cancel

that of the other, so that practically no heating would result. This is an

important consideration in the construction of coils of this type, particularly

where multiturn and series type heating coils are needed.

A multiturn coil of the series type arranged for hardening two surfaces is

illustrated in Fig. 64. While applications of this type can be provided for as

shown, there are bound to be some losses due to the length of the leads between

each coil section and, before the adoption of multiple heating as illustrated,

the advisability of hardening the surfaces separately should be considered. In

any case, a coil of this type should be so arranged that the leads are close

together and never as indicated by the dotted lines, for the inductance

resulting from the jumper and the input leads which would cause heat losses.

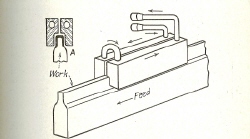

Fig. 63 - When making series-type coils,

particularly those of the flat type, it is essential that all turns be made to

carry the current in the same direction, as shown at the left.

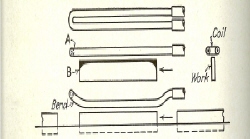

Fig. 64 - In constructing a series-type coil as

shown here, it is important that the leads be kept close together in order to

assure maximum heating to the areas on which heat is required.

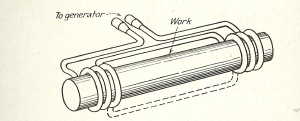

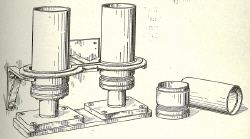

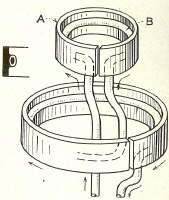

Fig. 65 - A series-type coil assembly,

comprising four multiturn coils, arranged for internal heating.

Multiturn copper tube coils of the series type can be made of a single piece

of tubing, as has been shown, whereas another practical design is that shown in

Fig. 65. Here the coils are made separately and joined together by bus bar

jumpers, or connectors. The hose shown at the top is used for providing a

continuous flow of water through all four coils. The two supporting members,

through which the copper tubing is assembled, are made of asbestos board.

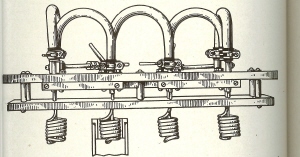

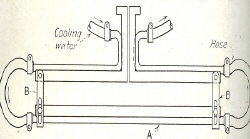

In Fig. 66 is illustrated a series-type internal-heating coil showing another

means of making a connection. Each coil is made separately and then connected

to a jumper plate A, through

Fig. 66 - Double-type internal-heating coils

arranged with a bus-bar connector and a hose for the continuous passage of

water.

which the high frequency current passes from one coil to another. The ends

of the coil tubing are then connected with a section of hose, to provide

continuous passage of cooling water. The other two ends of the coils are

connected to the output leads of the high-frequency generator. This design can

be used for a greater number of coils, which may have to be joined together and,

where operating conditions permit, operated in series.

A multiturn coil used for brazing together two steel sections in which heat

is desired from the inside surface is illustrated in Fig. 67. The part has been

cut in half to show the relative location of the coil. When long leads are

required, as is true in this case, it is necessary to keep the leads close

together, particularly where they enter the bottom opening, like that shown. It

must be remembered

Fig. 67 - A series-type internal-heating coil

with two separate coil units, which is used for the brazing of two steel cases

simultaneously.

that if the leads lie adjacent to a metallic surface, thy will generate heat

where it may not be wanted and dissipate some of the energy needed for a

particular portion. In this case, the leads are mounted in insulating blocks

attached together but separated by mica insulation. for the operation shown,

the two pieces are handled in one setting and the two coils are series

connected. All lead connections are made on the underneath side of the table

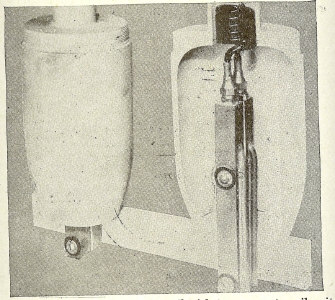

The coils shown in Fig. 68 is an excellent example of a solid-type inductor

for heating two parts at one time. The coil is made from a plate of copper 3/8

in. thick and bored out to provide suitable clearance around the two work pieces

to be heated. The copper tube, used for cooling, may be seen around the outside

edge of the coil. The coil is supported by two angle plates connected to the

front panel of the worktable. Since the panel is made of insulating material,

the brackets have no means of shorting the high-frequency current. When making

supports for coils it is important to provide proper insulation. The coil is

used for brazing two steel tubular parts together, like those shown at the

right.

A series-type coil made from several copper bushings attached together

around the upper and lower portions of the bushing are brazed the copper tubes

used for cooling.

Fig. 68 - Tandem design heating coil of the

single-turn type used for the brazing of steel tube assemblies.

Saw cuts are provided between the bushings in order to provide for a

continuous path of high frequency current. The operation in this case is the

brazing of a steel tube to a cap. The coil and fixture are arranged so that

eight parts are completed simultaneously. A coil of this type is relatively

easy to build and may be employed in a variety of operations requiring

multi-setups.

The same general principle is applied to series - type coils made from a flat

copper plate, like the one illustrated in Fig. 70. Here the cooling tube is

brazed on the underneath side of the plate and shaped to conform to the coil

openings. The tubing connections are brought out at one side, to provide a

suitable connection to the output leads of the generator. The coil is provided

with small end plates, as at A, to which supporting braces can be attached, to

provide for rigid mounting.

Fig. 70 - A heating coil made from a flat copper

plate and provided with a cooling tube, placed on the underneath side, is

illustrated above.

High-frequency current will circulate around the surface of the metal part

even though this is not completely surrounded by a coil. Naturally there are

limits in the extent to which this principle can be applied, but for average

small parts, usually requiring high-frequency heating, it is possible to use two

parallel inductors and to pass the work underneath, or arrange it in approximate

relation to the inductors, so that heat will be absorbed around its entire outer

surface. This principle is illustrated in Fig.76. Here, at A may be seen the

relation of two parallel inductors used for soldering a cover plate to the body

of a round condenser can. In this case the heat is

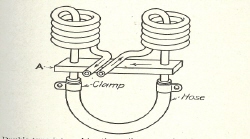

Fig. 75 - Another form of series type internal

heating coil. Copper tubing is used for connecting both sections, as well as to

provide for the flow of cooling water.

Fig. 76 - An example of parallel-type inductor,

comprising two bars, which is used for the soldering of condenser

ans.

concentrated to the edges only. For the example

shown at B, the inductor bars are located directly above the joints to be

soldered, which in some cases will be found preferable. The principle of

heating is shown below. It will be seen that the high-frequency current

circulates through the bars of the coil which, in turn, is induced into the work

located underneath in the opposite direction. In handling operations of this

kind, the work can either be placed in a fixture that provides correct relation

to the inductors, or conveyor-fed progressively under the inductors.

Another form of inductor, comprising two bars, is illustrated in Fig. 77.

Here the longer bar A is adjustable by means of the jumpers B. As will be seen,

the bars are provided with cooling

Fig. 77 - A two-bar parallel inductor of the

adjustable type is shown above.

tubes and have hose connections at their ends for the continuous passage of

cooling water.

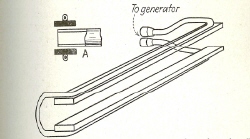

The coil shown in fig. 78 also is of the two-bar type and is arranged so that

work can be passed through the opening, as illustrated at A. The part

represents the end of a drawn-steel shell which requires annealing. The

operation is performed by feeding and rotating the work through the bars,

starting at one end and leaving at the other. In mounting coils of this type,

it is necessary to provide suitable supports, such as stand-off insulators, in

order that rigid mounting can be obtained.

In Fig. 79 is illustrated a two-bar inductor of the parallel type used for

the heating of a long steel bar requiring hardening at one edge only. In this

example the inductors are cut out to conform to the shape of the part, as shown

in the cross-sectional view at A. Holes are drilled lengthwise through the

inductors for the passage of cooling water. At one end a jumper is provided,

whereas at the other end of each bar the terminals connected with the generator

are brought out. Coils of this type can be insulated by means of mica, in which

case it is possible to provide a means for clamping them firmly together. The

sectional view taken through the inductors shows the work in the heating

position. Only the edge of the bar is heated as it is progressively fed through

the inductors. A spray

Fig. 78 - A two-bar-type inductor arranged so

that the work can be rolled between the plates as may be required for annealing

the ends of shells or tubes.

quench unit, not shown, is located at the left of the inductor, in order to

complete the hardening cycle.

In making heating coils for continuous feed operations, it is often desirable

to use copper tubing

Fig. 79 - A solid-type parallel inductor used

for the transfer of heat to the edge of a long shear blade, requiring

progressive hardening.

made into the form of a hairpin, under which the parts to be heated are fed.

With such a coil it is often necessary to bend the end of the coil upward, as

illustrated in Fig. 80. If the coil remains on a true horizontal plane, as

illustrated at A, there may be a likelihood of excess heating on the edge of

the work, as at B, especially is sharp corners are encountered. Usually the

thinner the work, the more necessary it is to provide this bend at the end of

the coil.

Fig. 80 - When using hairpin-type coils for

heating the edge of narrow strips, it is advisable to turn the end of the coil

upward to avoid overheating on the corners of the work.

|