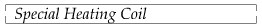

Two-piece Coils. A split-type coil like that used to heat a part

having flanges on each side of the bearing surface is illustrated in Fig. 55.

In each section of the coil are separate cooling tubes, which in turn are

series connected for the continuous flow of water. Both sections are held

together by a clamp, although various other means of connecting may be used.

One of the pieces to be heated is shown at the right of the coil.

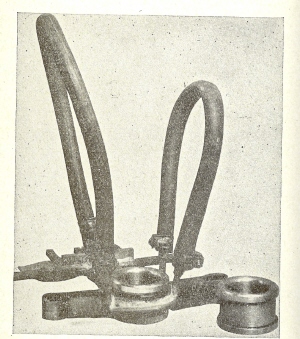

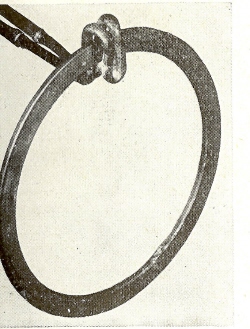

A hinged-type inductor of solid design used for the hardening of crankshaft

bearings is illustrated in Fig. 56. The coil is arranged so that after the work

has been properly located and centralized within

Fig. 55 - A typical single-turn heating coil of

the split type, which is used to heat the small diameter of a flanged

part.

it, the upper half of the coil is brought into contact with the lower half,

thus completing the electrical connection. Both coil sections are held together

with pressure during the heating operation. Also, both sections of the coil are

provided with internal passages for cooling purposes, with suitable quenching

chambers to make the quenching water pass directly through the area of the

coil's heating surface. The cycle for the operation is controlled by a timer

and functions as follows:

1. The coil is closed.

2. High-frequency heat is generated to the work's surface.

3. The quench is applied.

4. Finally, the coil is opened so that the work can be removed.

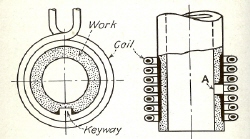

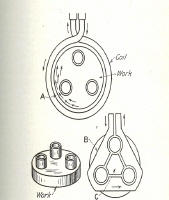

When applying high-frequency current to surfaces which include keyways, or

holes like those illustrated in Fig. 57, the eddy currents concentrate at the

corners, probably casing some overheating. With the keyways as shown the edges

will heat rapidly and a slight burning action might take place. To overcome

this, the part can be fitted with a copper key to bridge this gap, thus making

the heating more uniform.

Fig. 56 - A well proportioned hinged-type

induction heating coil used for hardening crankshafts bearings.

In case a part having a hole through the surface is to be heated, as shown at

A, the magnetic flux from the coil will tend to enter the hole and develop

maximum heat around the edges. To reduce this condition the hole can be

provided with a copper plug which shunts the opening and thus reduces the

absorption of eddy currents at this point.

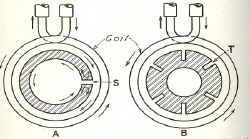

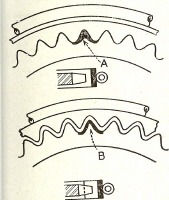

In heating a slotted part within a cylindrical coil, as shown at A in Fig.

58, the circulating current on the surface of the work piece naturally is

interrupted by the slot, but the current will continue to flow

Fig. 57 - Overheating of sharp corners, such as

keyways and holes, often takes place and the use of copper inserts may be

advisable to shunt the path of high frequency current.

on the inside because of the nature of high frequency, which must form a

closed circuit. When treating pats of this design, therefore, a somewhat higher

heat usually is produced at the edge of the slot, as indicated at S. With the

multi-slotted part as shown at B, the circulating current around

Fig. 58 - In heating shaped parts such as those

shown in this example, the high frequency current tends to crowd into the slots

resulting in overheating.

the work piece will have a tendency to crowd into the slots T, and again an

overheating condition is most likely to occur on the corners. The thinner the

coil in relation to its diameter, the more pronounced the heating at the slots.

On the other handle, with the use of a heating coil having a height greater than

its diameter, this condition will be less pronounced.

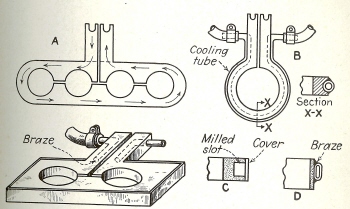

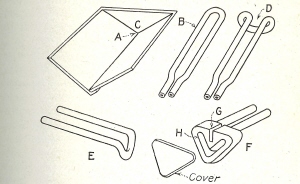

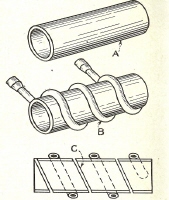

Single-turn Coils. Solid-type induction coils are made of sheet

copper, as illustrated in Fig. 59, and can be arranged for single or multiple

operation. The coil shown at A, which is typical for heating

Fig. 59 - Constructional details of single-turn

coils made from flat copper plate and provided with means for

cooling.

parts simultaneously, is made of a thick copper plate, bored to provide

coupling sufficient for the diameter. Two connecting blocks are brazed to this

plate, and then the plate is sawed out, as shown, so that the high frequency

current will follow the path of the arrows, coming in at one block and going out

at the other.

At B is a single-station coil of similar design, showing a suitable method

for providing the necessary cooling. A groove is milled around the coil, and a

copper tube is brazed in place. At C is shown another solid-type inductor, in

which the cooling chamber is provided by milling a slot around the outside edge

and brazing a sheet-metal cover over it. The water outlet to the two connectors

is made by drilling a hole through them and connecting a small tube, as shown.

Another type of solid inductor is illustrated at D. This includes a band of

copper to which a section of flattened tubing is brazed to the outer edge.

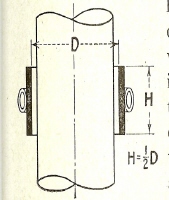

In making the so-called solid-type inductors, which comprise a single-turn

coil, it is best to consider the proportions shown in Fig. 60. It will be seen

that the height of the coil is equal to one half the diameter. These

proportions can be exceeded in certain cases and various modifications are

Fig. 60 - In making single-turn coils it is well

to keep the over-all height to approximately one-half the diameter as

shown.

possible, but it is usual to limit the use of solid inductors to applications

in which the height or length of the heat zone is less than the diameter of the

coil. When a longer area requires heating, multiturn coils may be used to

better advantage. If the area to be heated is exceptionally long, progressive

feeding may be the solution.

the length of the heated zone of a shaft placed within a cylindrical coil

will usually exceed the over-all height of the coil at both ends by a distance

equal to the coupling C, as shown in Fig. 61. This overlap is indicated at E in

the illustration. When the thickness of the coil T is increased, as shown,

there is a tendency for the heating zone to spread out still farther on each end

of the coil, as indicated at F. This heating action is the result of a wider

distribution of magnetic flux, which develops from a thicker heating coil. The

same condition also exists in either case, when using multiturn copper-tube

heating coils.

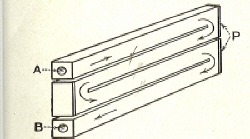

Miscellaneous Coils. In Fig. 81 is illustrated a flat type coil,

which has broad uses in the heating of parts requiring uniform heat. This coil

is made from a flat piece of copper. First, four holes are drilled through the

entire length, then the slots are cut as shown, so that the current will

circulate back and forth, entering through the connection at A and leaving at

the connection B. At the end of the coil, where provision is made for

circulation of the cooling water, the small plates P can be attached, as

indicated. Coils of this type can be made in various sizes and styles, and are

particularly suitable in cases where a single hairpin coil is applicable.

Fig. 81 - A flat-type coil made from a block of

copper, with drilled holes for passage of water and slots cut between sections

to distribute the passage of high-frequency current.

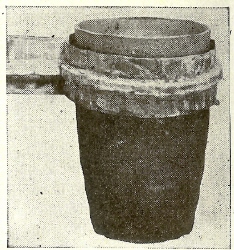

The coil shown in Fig. 82 is used for the heating of the end of a drawn cup

which requires forging. The coil in this case is made from a strip of copper,

to which a cooling tube is brazed, as may be seen. The area of the part to be

heated is approximately 2 in. in length and the temperature required is

1800˚F. The coupling of the coil is approximately 3/16 in.

In using coils of this type, a very even distribution of

heat can be produced, but solid coils of the same type are limited in their

height. The proportions shown in this particular coil are very satisfactory,

however, and the example is representative of the possibility of providing a

high temperature heat to a localized surface. In other methods it should be

necessary to heat the entire part, which often is objectionable. With

high-frequency heating the temperature change is so localized and so quickly

applied that the part can be removed by hand and inserted into the forging press

without insulating precautions that normally would be required.

Fig. 82 - A large single-turn coil used for

heating the end of a drawn steel shell, for a forging operation.

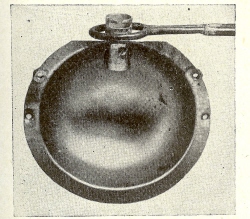

A single-turn coil used for soldering a socket to a reflector is illustrated

in Fig. 83. The socket is assembled to the reflector body and a ring of solder

is placed in the joint. Because of the thickness of the joint of the parts to

be heated, the heat is quickly applied and as a rule the coupling of the coil

can be made somewhat greater then for the average heating operation,

particularly where a greater

Fig. 83 - A small single-turn coil used for the

soldering of a socket to a reflector.

mass of metal is to be considered. The spacing of the joint where the coil

meets should be held to a minimum, so that even distribution of flux density

will prevail. Soldering operations of this kind can be effectively handled in

multiple, using a series-type coil.

In Fig. 84 is shown a double hairpin-type coil used for joining a steel

ring. This coil practically

Fig. 84 - A double hairpin-type coil used for

the joining of a steel ring.

surrounds the surface to which heat is to be applied, as will be seen. A

soil of this type can be made to heat a wide variety of surfaces and because of

its simplicity in design can be quickly formed.

Sometimes it is necessary to apply heat to the corners of an assembly such as

shown at A in Fig. 85. In this case an analysis has to be made of the

magnetic-flux dissipation from the coil to insure uniform heating. The use of a

hairpin coil, as shown at B, would result in the absorption of some of the

energy on the end plate C rather than in the corner. This would indicate that

the coil should be provided with a formed end as shown at D, in order to provide

for an extra amount of flux to this corner area.

On other parts presenting a similar condition, it would be possible to use a

coil formed on the end, as shown at E. Still another way to insure maximum flux

density in corners is to make a heating inductor as illustrated at F. In this

design, the ends of the connecting tubing are fastened to a small copper block.

This block is provided with a saw cut at G, so that the high-frequency current

will pass down to the corners. The end of the block is milled out for the

circulation of cooling water, as shown at H. A cover plate is then attached to

the face of the block to complete its structure.

In Fig. 86 is represented a piece of work requiring the heating of three

inserts for brazing purposes, for which a specially formed coil should be

provided. Assuming, however, that a symmetrical coil were used, as shown at the

upper portion of the illustration, there would be a tendency for the

Fig. 85 - When heat has to be thrown into a

corner, it is usually necessary to provide a coil which will transfer an extra

amount of heat to this joint.

Fig. 86 - Principles involved in brazing three

lugs to a cap by means of a single-turn coil, showing the correct and incorrect

methods.

circulating current to crowd through the narrow portion of the work, as shown

at A, and excessive heating would take place. Also, there would be insufficient

heat at the inside portion of the insert.

To handle such an operation a series-type heating coil, as shown at B would

be required. In that case the high-frequency current would enter at one

connection, then completely surround the three inserts, and pass out through the

other connection. It would be necessary, however, to use a coil inset, as shown

at C, which would act as a flux concentrator. In making such a coil it would be

necessary to provide cooling not only for the outer section, but also for the

insert.

When hardening the outer surface of a part having a variation in depth, such

as the sprocket shown in Fig. 87, there would be a tendency for the outer

portion of the teeth to absorb more heat than at

Fig. 87 - When heating irregular surfaces such

as sprocket teeth, it is essential to use a formed coil, usually of the cast

type, in order to assure uniform heating.

the root. Assuming that a single-turn flat-type induction coil were used, we

would get a heat pattern such as that shown at A, on which the points might

become overheated. To overcome this condition, the coil should be made to

conform to the approximate outline of the teeth, like that shown in the lower

portion of the illustration. A coil of this type can be cast to size and with a

carefully made pattern should require very little cleaning to assure uniform

heat. With a formed coil of this type, the heated zone will be produced as

shown at B, with a more uniform density of heat around the entire profile of the

tooth, especially at the root.

Sometimes it is necessary to provide a tubular-type coil for maximum heat

concentration to the surface of a part, where a solid-type inductor might be

preferred to a multiturn coil. The design of a coil for such an operation is

illustrated in Fig. 88. A copper tube of the size required is cut off as shown

at A, then a section of small tubing is wound around the outside, as illustrated

at B. Finally the coil is saw-cut with a spiral, as shown at C.

An induction-coil assembly for the heating of continuous strip this coil is

longer in relation to its diameter than would normally be necessary for

hardening operations, but in cases where continuous heating of material is

desired, a coil of this type works satisfactorily. In this application, the

heating-coil unit is placed adjacent to a power press. The material being

heated is a magnet-steel strip which is heated to 1800˚F, then

blanked, formed, and hardened in one operation. The temperature attained in the

steel as it enters the press is slightly higher than that required for

hardening, but during the blanking and forming operation the temperature drops

to approximately 1525˚F, then quenched in oil. The steel is 1/8 by 5/8 in. in

size and is heated by a 30 kva input high-frequency unit. As a result of

high-frequency heating, the steel receives a higher indexing magnetism and a

better magnet is produced. Another direct saving is a marked reduction, or

practical elimination, or rejects.

Fig. 88 - Constructional details of a

spiral-type coil made of a copper sleeve to which copper tubing is attached for

cooling purposes.

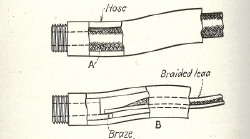

Flexible leads can be used with induction heating setups, although their

application should be limited to heating requirements which might make them

necessary. These leads can be made from sections of high-pressure metallic

tubing of the flexible type, as illustrated at A in Fig. 90. It is essential,

however, that the braided cover, as well as the inner bellows, be made of a pure

copper, having high electrical-conductivity qualities. For safety it is well to

provide a rubber hose on the outside, as indicated. Leads of this kind provide

for the passage of high-frequency current from the generator to the work coil,

as well as for the passage of cooling water.

Fig. 90 - Two types of flexible leads which can

be used in connection with induction-heating generators.

Another way to make a flexible lead is illustrated at B. Here the

braided-copper lead is brazed to the connector and then covered by a rubber hose

as shown. With this type of lead, it is necessary to have a similar connection

at the other end for attaching the work coil.

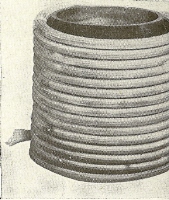

In Fig. 91 is illustrated a multiturn coil provided with insulating in the

form of woven glass sleeving. About the only advantage of insulation of this

type is the elimination of metal-to-metal contact of the coil windings, which in

this case are very close together. Where intense heat is to be applied,

however, insulating material of this kind does not give long service and other

means of insulation are more practical. A copper-tube coil can be lacquered,

or coated with insulating varnish, then baked, if its use is not in connection

with flux as used for brazing. Plating is not usually recommended, since

high-frequency current travels on the surface of a coil, and plating materials,

such as chrome, are not good conductors. Ceramic cement provides good

insulation around a coil and may be used where protection is desired.

Fig. 91 - A multiturn heating coil covered with

woven-glass sleeving. Coil insulation can also be obtained by applying a baked

coat of insulating varnish.

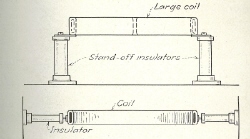

Fig. 92 - Large heating coils can be supported

by stand-off insulators, in order to assure rigid mounting.

Heating coils sometimes require outboard-supports, because of their sizes and

shapes. While such supports can be provided in various ways, it usually is best

to consider an insulator that will prevent the loss of high-frequency current

from the coil. A satisfactory type of support is a stand-off insulator, as

illustrated in Fig. 92. Small extensions can be brazed to the bottom, so that

a rigid coil mounting is provided. It also is possible to support induction

heating coils from their sides, as shown in the lower portion of the

illustration. In this case, the end of the stand-off insulator is brazed to the

side of the coil, then the base of the insulator is mounted to some convenient

vertical support at the sides.

Many other forms of brackets and supports can be used for coils and, in cases

where insulating material such as asbestos board is used for the top of a work

table, there is no objection to providing copper feet or legs in the coils for

alignment purposes. Other means of supporting coils may be seen in various

illustrations showing hardening and brazing installations.

|