Coils for high frequency induction heating can be made in a wide variety of

styles, shapes, and sizes. Their design usually is governed by the nature of

the component to be heated and by the type of generator used. Briefly, coils

can be of the single-turn or multiturn type, fabricated, multiple,

series-connected, or cast to shape. However, some high frequency generators are

limited to certain specific types of coils, because of the impedance of their

tank circuits which may limit their use to multiturn coils. In view of this

condition, the power source must be taken into account before a heating coil is

designed. Other generators, however, are provided with means to match

practically any type of heating coil so that a much broader selection of coil

designs is made possible.

In describing different types of heating coil for inductive operations, it

would be difficult to cover all the different types of condition which arise,

such as the shape and size of the work piece, the nature of the surface to be

heated, and its relation to the heating coil. However, from the variety of

heating coils shown, representing the designs most commonly used, together with

some of the basic principles involved, a good conception of the importance of

coil construction will be gained. The designs represent coils that will service

the need for a wide variety of heating operations, and that with slight

modifications will cove the majority of heating applications encountered.

Perhaps nothing is more important to induction heating than the coil itself.

Next is the source of power, which must be suited to particular operation

contemplated. It is here that frequency and volume of power show their

possibilities as well as their limitations. But with suitable high frequency

power it is on the coil that we depend for the correct distribution of heat

within a metal part.

If we consider a heating coil as a means of transferring heat by eddy

currents, and then consider the shape of the coil in relation to the work's

surface, we can see that the heat pattern will closely resemble the shape of the

coil, more so with a close coupling than where the work and the coil are farther

apart. The problem therefore is to make the coil of correct shape to surround a

surface to be treated and then space it according to the amount of heat needed.

As the coil is placed farther from the work, the eddy currents spread out in

wider form and cover a larger surface. Coupling, therefore, is an important

consideration.

Not always is maximum heat transfer the most desirable factor.

Often a slow, even heat distribution is outstanding need. For general hardening

purposes a quickly and rapidly heated surface usually is desired. For soldering

a slower penetrating heat might be more desirable. For brazing a

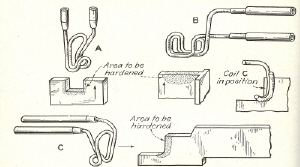

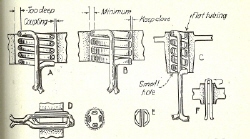

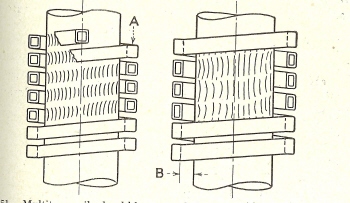

Fig. 37 - A variety of heating coils used in

connection with induction heating equipment, including those of the single and

multiturn types.

somewhat in between heat might be required, since rapid heat might cause

blistering and a slow heat would result in lost time or the heating of unwanted

areas.

Types of Coils. In Fig. 37 are illustrated some of the more commonly

used coils as applied to induction heating equipment. The general purpose type

most used is one shown at A representing the multiturn design, which is would or

formed from copper tubing, either symmetrical in contour or shaped to suite the

outline of the part to be heated. Solid-type inductor coils, like the one shown

at B, are also widely used and are particularly suitable for heating of parts

where a restricted heat zone is desired. The coil shown at C is of series

design, which makes possible the heating of several pieces at onetime. The coil

at D is made of flat strip, which, as may be seen, may be used in a variety of

heating operations.

Regardless of the types of coil used, it is necessary to provide cooing,

which in the case of the multiturn coil is accomplished by circulating a flow of

water through the coil itself. With the single-turn inductors, cooling is

accomplished by adding a copper tube to the outside or by other suitable

cavities for the passage of water.

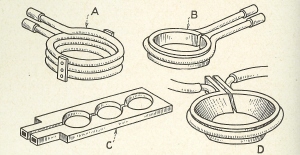

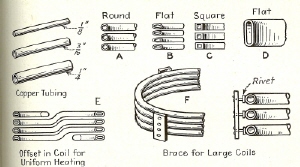

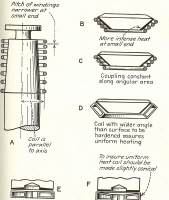

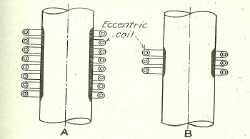

Fig 38. - Multiturn coils can be formed to

various shapes and usually have a wide latitude of applications in connection

with induction heating work.

All heating coils, regardless of their design or shape, should be made of

copper having a conductivity of 90 per cent or more. Pure copper unquestionably

serves as the best material for coil construction.

Multiturn Coils. In making multiturn coils of copper tubing, a wide

variety of shapes is possible, as shown in Fig. 38. The most common is a

cylindrical coil, as at A, which is suited to surface-heating of shafts and

round parts. The rectangular or square coil at B, as well as the cam-formed

coil at C, also is used for heating the outer surfaces of bars or shafts and can

be easily formed and would over a wooden block. The pancake coil at D is used

for heating flat surfaces, such as clutch jaws, or ends of shafts, while the

spiral-helical coil E is used for heating conical surfaces, such as bevel

gears. The coil at F is of the internal type and is used for heating inner

surfaces of holes.

Other suggested types of induction coils made of copper tubing, arranged for

heating irregular surfaces, may be seen in Fig. 39. The coil at A heats the

surface around the slot, while the one at B heats the end section of a formed

steel bar. Coil C, somewhat similar in shape, heats on edge and the fillet of a

plate, one view of which illustrates the coil in position during heating. With

irregular surfaces such as these, requiring coils of intricate shape, it is

often necessary to experiment until

Fig. 39 - Copper tubing can be formed into

various odd-shaped coils, as shown, for the localized heating of metal

parts.

the correct heat pattern is obtained. Sometimes only the spreading of the

coil, one way or another, might offer the results desired, whereas in other

cases a completely new shape may have to be wound.

In Fig. 40 suggestions are shown for the construction of copper-tube coils.

Such coils usually are made of tubing ranging from 1/8 to 1/4 in. in diameter.

The 1/8 in. size should be used very sparingly, however, because of its small

area and since the flow of cooling water is likely to be too small to prevent

overheating. For short heating cycles, where a slight heating of the coil may

have no effect, this size could be considered. However, the two larger sizes

are preferable.

Round copper tubing can be used for many types of coils, as shown in A,

although it is usually preferable to flatten the tubing as illustrated at B.

Another practical form is the square or rectangular shape shown at C. It also

is possible to use a larger diameter tubing, such as 5/8 or 3/5 in., as shown at

D, and to produce a flat coil similar to a solid inductor previously

mentioned.

In making helical copper-tube coils where a restricted heat zone is desired,

the coils should be made with an offset, as shown at E, so that uniform heating

can be provided. At F is shown

Fig. 40 - Constructional details of copper-tube

heating coils of the multiturn types are shown here.

a means of providing a brace for large-diameter coils, which might have a

tendency to sag or go out of shape. These braces provide unusual stiffness and,

as shown, are attached by brazing small rivets to the coil section and heading

the rivet over on the outside of the braces. These braces can be made of thin

asbestos board, or a laminated plastic material.

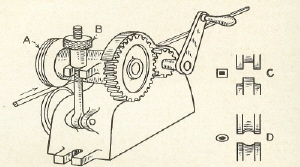

A suggested form of tube flattener for use in the making of heating coils

requiring square, oval, or other formed sections, is illustrated in Fig. 41.

This device consists of two formed rolls, through which the copper tubing is

passed. Feeding of the tubing through the rolls is done by means of the hand

crank. The upper roll is mounted on a hinged bracket, which is adjusted. to

correct relation with the lower roll by means of the hand knob B. At C is shown

the type of roll which can be used for forming a square-shaped section from a

round tube, whereas at D is illustrated the roll used for providing an oval - or

flat - shaped tubing.

Fig. 41 - A hand - operated tube flattener,

provided with forming rolls, can be used in the construction of heating coils

requiring flat tubing.

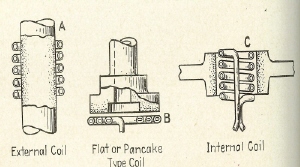

Heating Rates. Because of the path of magnetic flux around a

cylindrical coil like that at A, Fig. 42, the greatest field strength will be

obtained within the coil itself, rather than on the outside. For this

Fig. 42 - Three most popular types of multiturn

coils are the external, pancake, and internal designs shown here.

reason outside surface-heating of parts, such as steel shafts, can be

preformed exceedingly fast. With a flat- or pancake - type coil, as at B,

heating will be somewhat slower per square inch of area, or roughly 75 per cent

that of the example at A. With internal-type coils, like those shown at C, heat

transfer is still slower, because less magnetic flux is concentrated on the work

surface, and may be heated only 50 to 60 per cent as fast as outside heating.

These estimates are based on the use of a high frequency generator of a given

output power. for non-ferrous materials heating times will be somewhat greater

than for ferrous materials, usually in the order of 1 1/2 or 2 to 1.

Internal Coils. since the density of the magnetic flux is less on the

outside than on the inside of a coil, and because the greatest strength lies

next to the coil, it is advisable to make internal coils in

Fig. 43 - Constructional features of internal

coils are shown here. Coils of this type should be made as thin as possible and

should be located close to the work's surface.

such a way that the over-all distance from the surface of the hole being

heated to the inner surface of the coil is held to an absolute minimum. In A,

Fig. 43, is shown a multiturn coil of usual design, which, when applied within a

hole, results in the dissipation of heat energy because of the excessive

over-all depth between the work surface and the inner diameter of the coil.

At B the condition is greatly improved, since the coupling between the work

and coil is reduced and since the coil is flattened. This means that the

over-all depth is held to a minimum, thus assuring maximum heat energy, the

magnetic flux being more constricted to the heated area. The coupling for

internal heating coils should be made no more than 1/16 in., and less if

possible.

Internal cols for hole heating usually are limited in size because of their

mechanical construction, and usually a 5/8 in. hole is the smallest that can be

heated with a multiturn coil, as shown at C. Another form of internal coils is

the double-turn coil, illustrated at D, in which the tubing is flattened to

provide for maximum heat transfer. In making coils of this type, care should be

taken to avoid closing in of the tubing, so that the water passage will not be

restricted. Also, because the hat pattern within the hole is likely to resemble

four longitudinal bands, the work piece should be rotated during heating. The

coil at E provides still another design using formed tubing, thus permitting the

coil to be small in diameter.

The hairpin coil at F also is practical for small-hole heating, but the part

must be rotated during heating to assure uniformity of heat transfer. Usually

internal coils of the types shown are limited to surfaces in which the height of

the heated surface is not more than twice the diameter. Where the length is in

excess of the ratio progressive heating should be provided if possible. In this

case the heat is concentrated to a small area of the hole, while the work itself

feeds at a uniform rate, depending upon available output capacity of the

generator, the size of the hole, and the area being heated.

When heating a tapered surface, the coil is usually made to conform with the

taper, although exceptions may be considered as at A, Fig. 44, which shows a

fixed-diameter coil arranged so that the pitch of the winding is wider at the

large end than at the small end. With this design, a greater concentration of

heat will be provided at the small end, because of the variation in pitch.

It is well to remember that with a fine-pitch coil the penetration of heat

will be deeper than with one having a coarser pitch. Usually the spacing

between cols should not exceed half the diameter of the coil, while smaller

spacing is preferable.

In heating conical parts, such as bevel gears, a coil with a consistent

spacing or coupling will result in a more intense heat at the small end, as

shown at B. To compensate for this condition, the coil should be made with a

wider angle at the small end, as shown at C, so that heating will be uniformly

distributed.

The same procedure is followed when using a solid-inductor coil, shown at D.

In heating flat surfaces, like that illustrated at E, a coil made parallel to

the face will have a tendency to create the greatest heat toward the center.

Coils for such surfaces, therefore, should be made slightly conical or angular,

as shown at F.

Fig. 44 - Coils provided with variations in

spacing between turns can be arranged to transfer heat uniformly to tapered

surfaces. Usually in heating tapered surfaces the coils should be made with a

wider angle than that of the work piece.

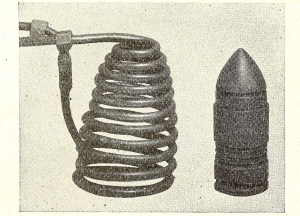

Distribution of Heat. An example of a multiturn copper-tube coil used

for hardening a projectile on which differential-hardness readings are desired

is illustrated in Fig. 45. The coil is made so that the hardness readings from

the point of the projectile to the base will taper gradually from 60 to 35

Rockwell C. In operation the part is heated and then quickly dropped into a

quench. The variation in heat and hardness is attained by a variation in

coupling, and in the pitch of the coil turns, which

Fig. 45 - A coil provided with variations in

turn spacing, which is used for the hardening of a projectile on which a

gradient of hardness ranging from 35 to 60 Rockwell C is

obtained.

as can be seen are wider at the bottom than at the top. This type of coil

provides for maximum heat where the hardest area is desired, and gradual

diminishing of heat for less hardness.

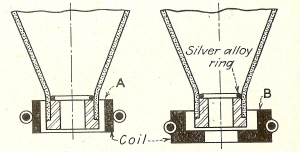

Fig. 46 - A single-turn heating coil used for

brazing a steel tube and an insert together. It is necessary to arrange the

coil so that the transfer of heat is concentrated on the heaviest section of the

assembly.

In designing coils for heating purposes, it is often necessary to analyze the

application to determine the best means of heat distribution. For the

application shown in Fig. 46, which requires the brazing of a steel insert to a

drawn-steel shell, the coils as shown at A might cause overheating of the then

material before the proper amount of heat could be conducted to the heavier

insert. This being the case, the outside surface also might blister and become

badly warped.

To overcome this condition, a coil such as that shown at B would be

desirable, since the generation of heat would be distributed more to the heavier

section, particularly at the bottom, and then would travel by conduction to the

remaining surfaces directly above. For heating operations of this kind, a solid

inductor of the single-turn, or even-series, type, is to be preferred. The coil

can be made somewhat higher than might be necessary. Then after observation of

the resulting heat the coil can be trimmed down one way or the other until the

exact heat pattern has been produced.

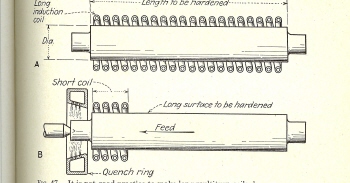

Fig. 47 - It is not good practice to make long

multiturn coils, because uneven heating is very likely to take place. In

heating long areas, it is better to use a short coil and feed the work

progressively through it.

Length of Coils. There is a limit to the length of surface which can

be heated at one time, and while no fixed rule applies, a helical coil usually

should not be more than three to four times its diameter, whereas a single-turn

coil will be found more effective when the length is not more than half the

diameter. The example shown at A in Fig. 47 obviously is too long, since too

great a surface is being heated at one time, causing possible deflection as well

as an uneven distribution of heat. For a surface of this type, assuming that

hardening is required, it would be much better to use a shorter coil and

progressively feed the part through it, such as is shown at B. The available

output power of a generator also is relative to the amount of surface that can

be heated at one time. IN this same example a generator with considerable power

would be required to heat the entire shaft at one time, as compared with one of

nominal power for the progressive-heating method.

Multiturn coils exceeding the proportions given can be sued for the heating

of this sections, such as steel wire and rod, especially in annealing

operations. For hardening and brazing requirements,

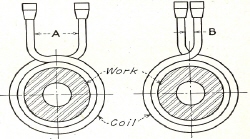

Fig. 48 - In connecting heating coils to

generators, it is well to keep the leads as close together as possible in order

to avoid inductance losses, which would detract from maximum heating in the

work.

however, exceptionally long heating cols may offer difficulties. Sometimes

it is this consideration that decides whether a job can best be performed by

inductive heating or some other method.

Inductance Losses. When connecting the leads of a heating coil to a

generator, especially those of the quick-change type, it is desirable to keep

them as close together as possible, in order to avoid inductance losses between

the leads, as might be represented by the example in Fig. 48. The spacing, as

represented at A, would result in some dissipation of the high - frequency

current, so that maximum heating of the work within the coil would not be

attained. By providing leads as shown, where the space B is held to a minimum,

there is a better assurance of maximum heating of the work within the coil.

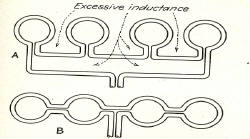

This same condition would be true in a series-connected coil, where

substantial losses will occur if the proper technique is not provided. The coil

shown at A in Fig. 49, for example, represents a very poor design, where owing

to its shape undesired inductance is set up between the coil sections. On the

other hand, the coil at B, which represents the same general type, is very well

laid out and would offer the assurance of maximum heat concentration to the work

pieces located in the openings.

Fig. 49 - In connecting series-type coils, it is

essential to make the connections in such a way that minimum inductance losses

will occur.

Pitch of Coil Windings. In applying multiturn coils for the heating

of steel shafts and other round parts, the pitch of the turn windings will have

a direct relation to the depth of heat penetration. With a find-pitch coil,

such as that illustrated at A in Fig. 50, the magnetic flux penetration will be

more highly concentrated on the surface of the work, with a resultant deeper

layer of heat. With an open-pitch coil, where the space between windings is

increased as at B, the penetration of heat to the surface of the work will be

somewhat less affected by the fact that the magnetic flux spreads out over a

wider area and causes certain losses. Usually in making multiturn coils it is

best to arrange the windings so that the space between turns will not be more

than one-half the thickness of the tubing itself. Beyond this limit, or with

loosely wound coils, non-uniform heating is likely to occur, and unless the

piece being heated is rotated the heat pattern on the work's surface will follow

the spiral of the coil.

When a steel part, such as a shaft, is heated at a comparatively fast rate by

a multiturn coil, there is likely to be a variation in temperature on the work's

surface because of the field set up by the spiral windings. The more open the

windings of the coil, the more pronounced will be the bands of heat, to a point

where the heated surface will follow the spiral form of the coil. For this

reason, the coupling, or spacing from the work to the coil is an important

consideration and, likewise, bears a direct relation to the pitch winding of the

coil.

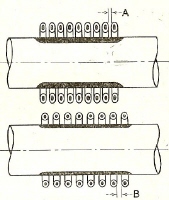

Fig. 50 - Coils provided with fine-pitch

windings have a tendency to throw a deeper layer of heat than those would with

loose windings.

With a coil like the one shown at A in Fig. 51, where the coupling is close

and the pitch winding of the coil loose, the heated zone will take on a bright

and dark pattern, following the exact shape of the coil windings. By increasing

the coil coupling, as at B, the heating becomes more uniform, though it

increases somewhat because of less flux-density transfer to the work's surface.

This heating effect is an important consideration when using multiturn

coils. It is most obvious when the spacing between coil turns is about equal to

the coupling, and diminishes as the tube spacing are reduced, in proportion to

coupling. The best procedure is to rotate the work within the coil so that

uniform heating is assured. This can be done in many cases by hand, if the part

permits, or by a motor-driven spindle, using a speed as low as 25 r.p.m., or

just enough to break up the uneven distribution of current density.

Fig. 51 - Multiturn coils should be correctly

proportioned as to space between windings and their distance from the surface of

the work, so that an even distribution of heat will be assured.

Naturally, the coil spacing around a part to be heated should be uniform,

especially if a uniform distribution of heat is desired. In some cases,

however, a slight amount of eccentricity between

Fig. 52 - If an eccentric coil is used to heat a

section of round steel, the variation in depth of heat penetration will be

proportionately greater with narrow coils than with high.

the work and the coil is not objectionable and may have no effect on the

heated area. This is usually the case when heating a small part and where an

ample amount of power is available. Where the rate of heating may be slower,

however, eccentricity of the coil may produce a variation in heat, the side

nearest the coil receiving the greatest amount.

With a high coil, like that shown at A in Fig. 52, a slight amount of

eccentricity will be hardly noticeable. However, with a narrow coil, as shown

at B, any appreciable amount of eccentricity or unevenness in coupling will be

more apparent in the form of heat variations to the work's surface. This is

quite noticeable in heating such parts as gears, especially when the thickness

is small in proportion to the diameter. Rotation of the work, of course,

offsets irregular heating due to slight

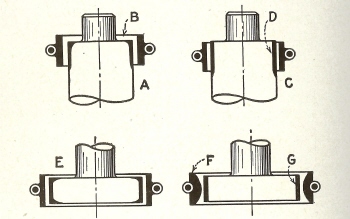

Fig. 53 - When heating coils overlap the edge of

a piece of work, there is likely to be overheating on the end surface. Placing

the coil slightly below the edge will produce a more uniform heat

pattern.

variations in coil couplings, as would be the case with an eccentrically

located inductor.

Heating Effects. When a cylindrical-type heating coil is placed around

the end of a shaft in such a way that it projects over the edge, as indicated at

A in Fig. 53, there will be a pronounced heating over the face as indicated at

B. If, however, the coil is arranged as shown at C, in which case the edge is

even with or slightly below the end of the work, the heat pattern on the surface

will be more uniform, as shown at D.

This same condition exists when heating a disk, or the flanged area of a

piece, as shown at E. The heat pattern will be such that the depth of

penetration will be less in the middle of the blank than at the ends. With some

parts it may be necessary to use a formed coil, as shown at F, with the inner

face made convex. This design provides for a uniform layer heat, as shown at G,

and eliminates the overheating of the edges which might occur with a straight

cylindrical-type coil. These same conditions apply to use of multiturn heating

coils.

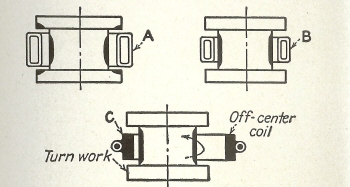

In applying heat to a surface which may have a shoulder or flange at each

end, as illustrated in Fig. 54, the spacing of the heating coil in relation to

the various surfaces becomes an important consideration. If the coil were

proportioned as shown at A, where the edges of the coil are closer to the

flanges than the central part is to the body, some heat would be applied to the

edges. This

Fig. 54 - In applying heat to flanged surfaces,

the relationship of the coil to the surface of the work is an important

consideration.

would result in the absorption of much of the flux density, so that the body

of the part would receive only a small amount of heat.

For such a surface, therefore, the coil should be made as shown at B,

arranged so that the coil is closest to the body requiring heat. In any case, a

split-type inductor would be required in order that the heat-producing surface

might be properly placed in relation to the surface requiring heat. For such a

part there is the possible use of a larger coil such as shown at C, through

which the work is inserted, and then positioned eccentrically as shown.

Rotation of the work is thus provided. With such a setup the flanges are more

liable to absorb some of the eddy currents, although the body will become more

predominantly heated.

|